P Id Drawings Explained

A guide to understanding p id drawings.

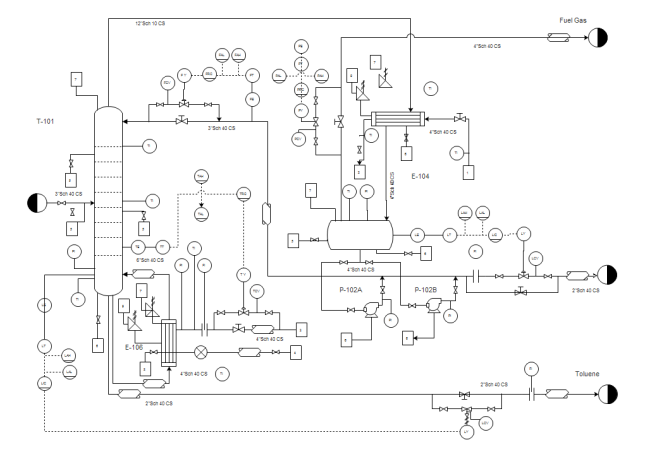

P id drawings explained. At first this p id looks complicated but on closer examination it is actually a simple p id. Subscribe https goo gl 9oktfa you will learn how to read p id and pefs with the help of the actual plant drawing. Let s confirm this with the help of actual p id. A guide to understanding p id drawings learning instrumentation and control engineering we provide tools and basic information for.

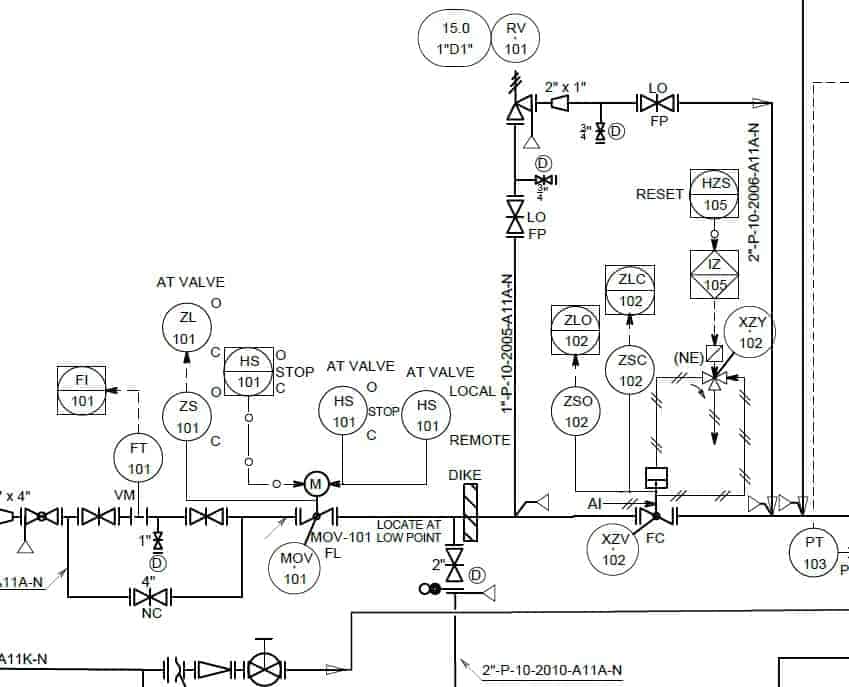

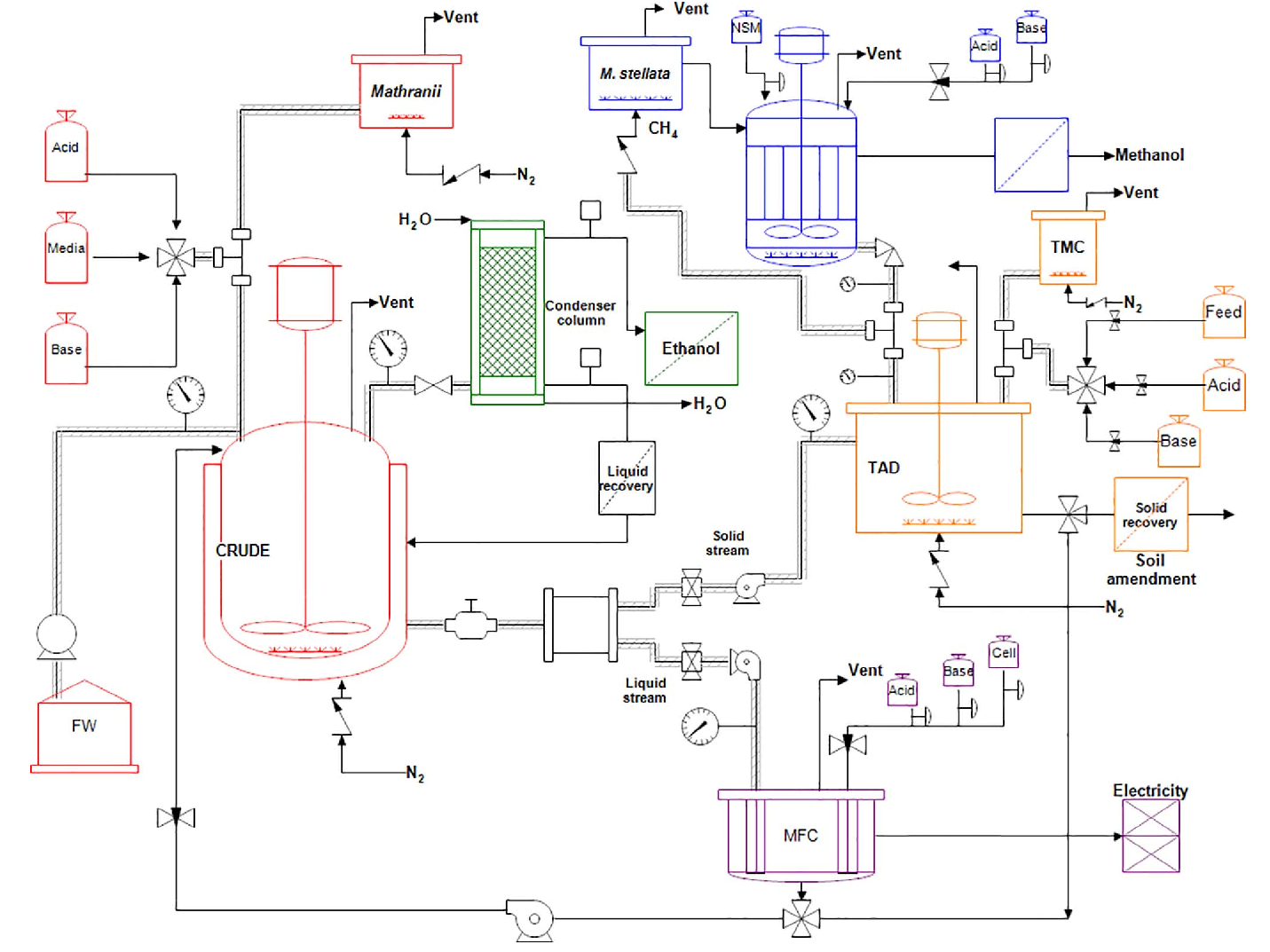

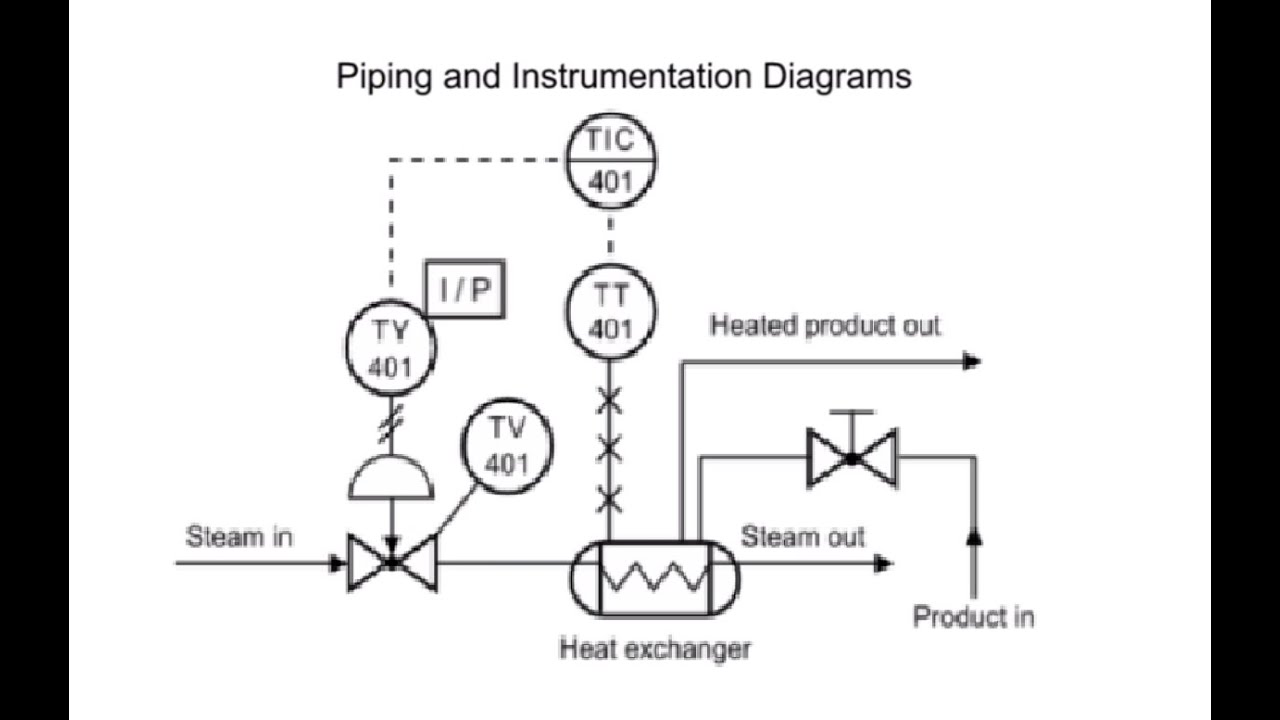

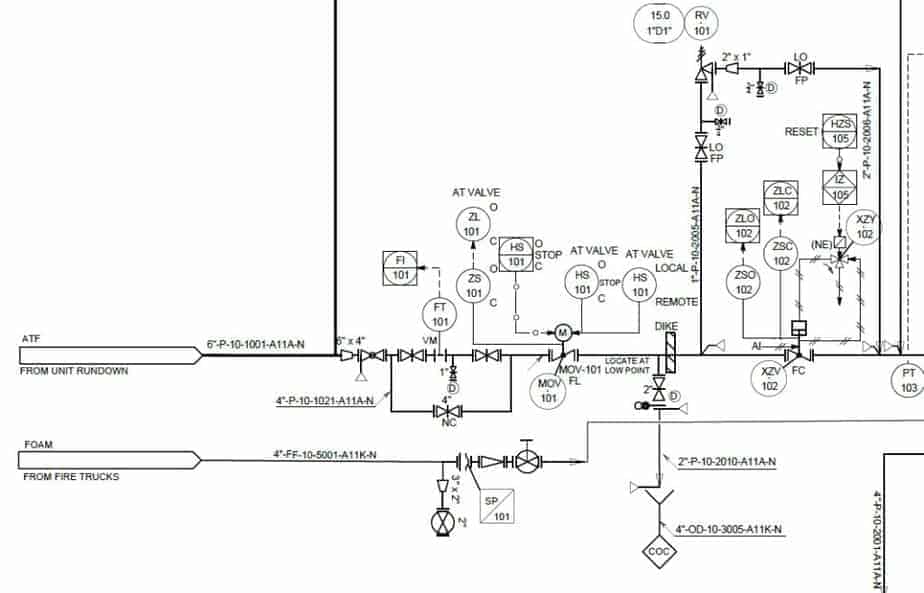

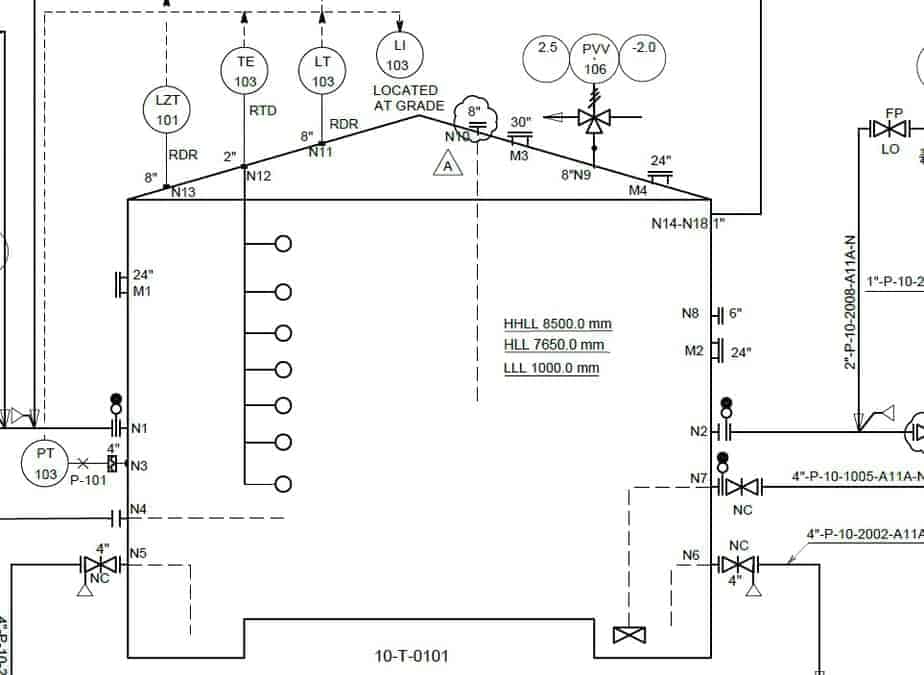

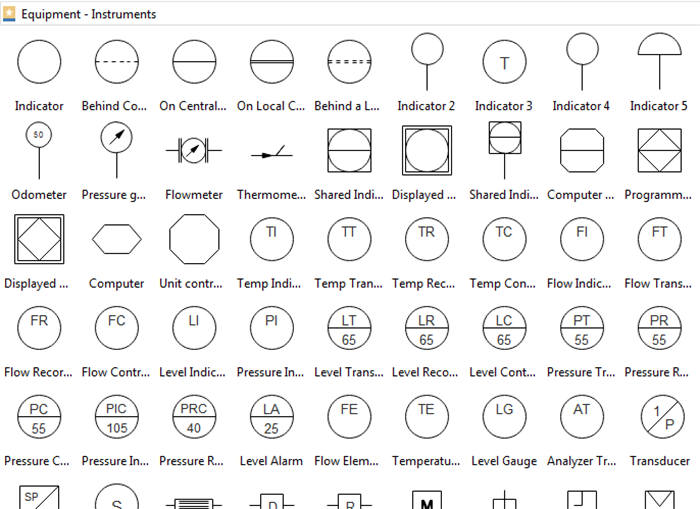

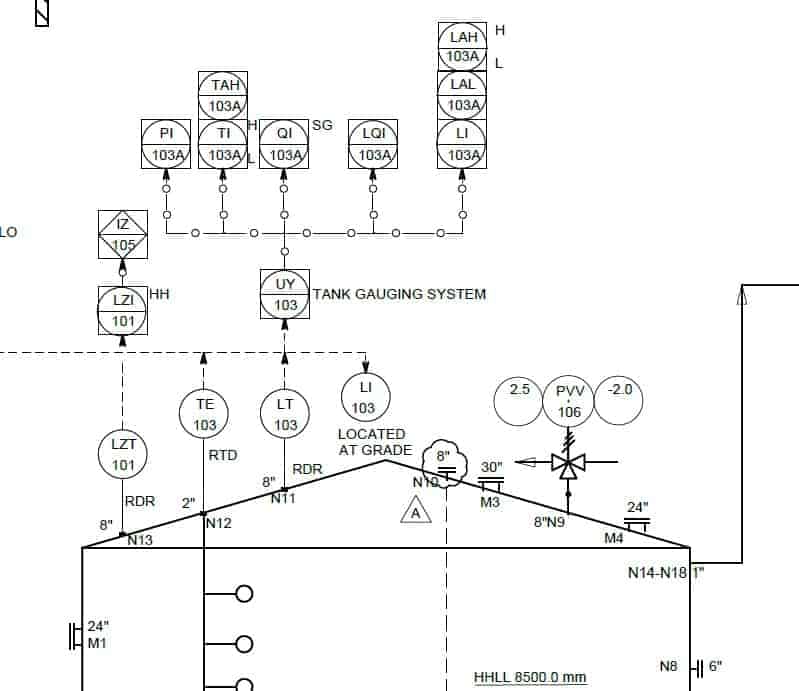

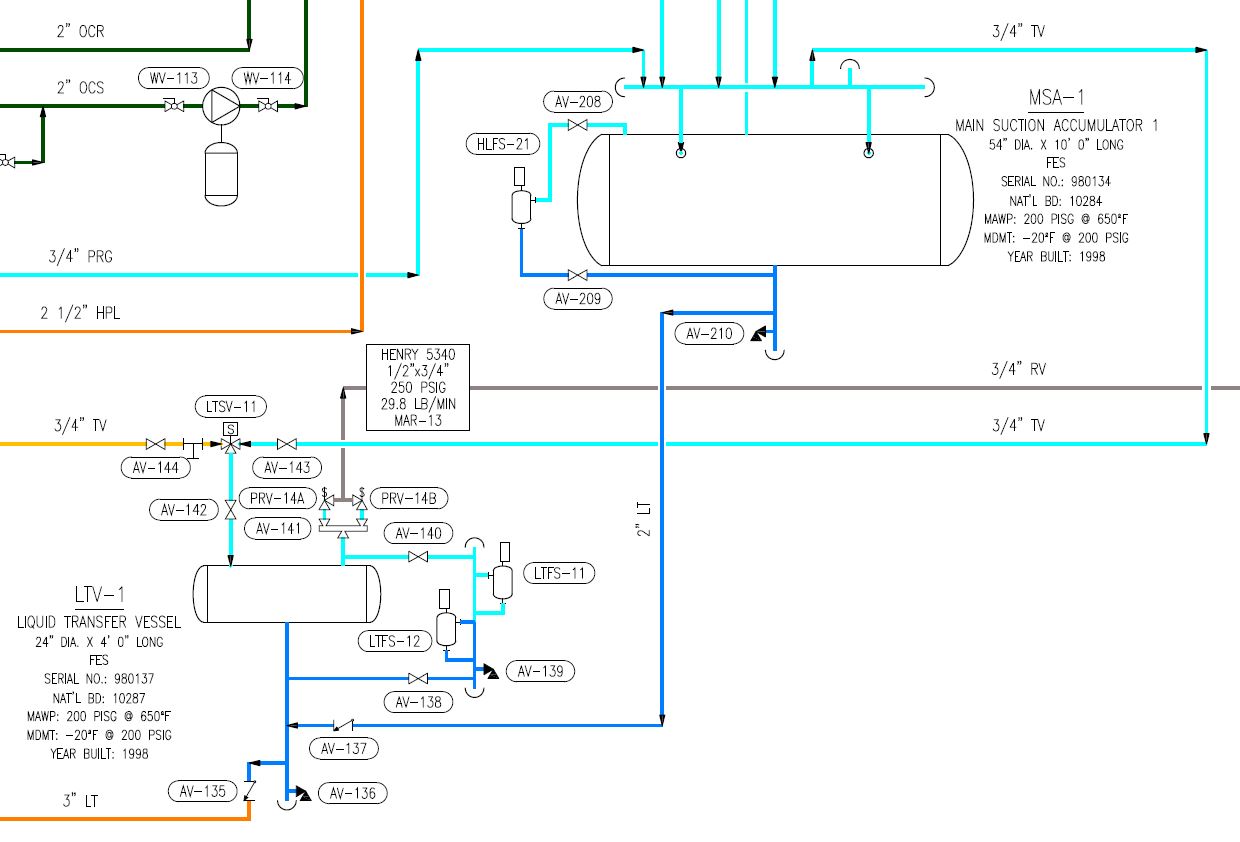

P id is the acronym for piping and instrumentation diagram i e. It is an essential document in the process industry. Drawings are comprised of symbols and lines that represent components or systems. A very detailed diagram showing the processes happening within a plant the involved equipment and their interconnections.

The p id diagram does not describe the chemical reactions involved in the process nor does it describe procedures of the same. Although a majority of the symbols and lines are self explanatory or standard as described in later modules a few unique symbols and conventions must be explained for each drawing. Support and structural details are also not included in p id. Learn how to read p id from the expert.

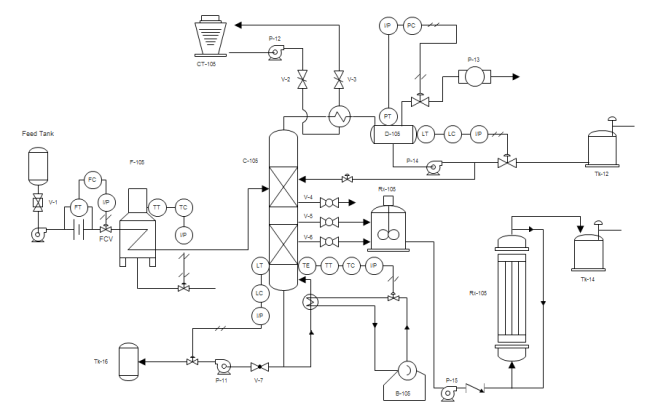

Piping and instrumentation diagram also called p id is a diagram used to show a graphical display of a complete system. Ok now you know what p id is and types of information you re going to get from the drawing. How to read the process flow diagram pfd this is a pfd of the flushing oil system that shows the entire system of pump seal flushing oil. Any change made in the process must be reflected in the diagram for example if an additional pump is installed it is important because your safety and that of your collaborators could depend on this action.

A piping and instrumentation diagram p id is a graphic representation of a process system that includes the piping vessels control valves instrumentation and other process components and equipment in the system. It includes all piping instruments valves and equipment that the system consist of. Superordinate to the p id is the process flow diagram pfd which indicates the more general flow of plant processes and the relationship between major equipment of a plant facility. Through a p id you can get the following information.